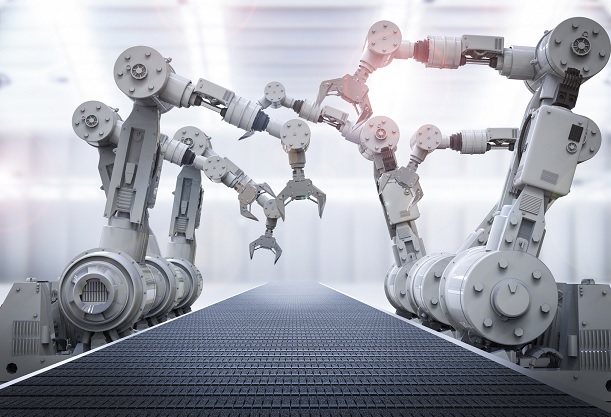

Huawei will research how 5G and cloud robotics can transform manufacturing after signing a memorandum of understanding with German automation company Festo.

The two companies will explore the Robot-as-a-Service concept, which customises robots and automated services for specific manufacturing tasks. Computing is shifted from the robot to the cloud, with a low latency 5G radio network used to link both.

Network slicing will be used to control the robot system, although the companies did not specify at which frequency band the research will take place. A so-called

Ultra Reliable and Low Latency Communications slice will fulfill the high performance requirements of the network. The cloud calculates the operation of the system as well as the ability to scale according to demand.

The project does not involve a network operator.

Dirk Pensky, Head of Festo’s Software Engineering Department, said: “In the factory of the future, everyone and everything will stay connected to rely on manufacturing services provided in industrial clouds.

“On the one hand, some of those services need high bandwidth to transfer information to and/or from the cloud, e.g. image processing and AR/VR services. On the other hand, industrial control services require low to ultra-low latency and highest reliability.

“Festo is involved in different activities to shape the future of our factories. 5G will become the communication technology for smart manufacturing and we aim to prove that with this cooperation.”

Yang Chaobin, President of Huawei’s 5G Network Product Line, added: “Mobile communications networks are developing and evolving rapidly, and will gradually penetrate a variety of vertical industries.

“5G will meet the diversified network needs of industry, enabling more vertical industry applications with end-to-end slicing solutions.

“Huawei…will work with vertical industries to explore new 5G applications and create greater value. Our cooperation with Festo will promote development of an intelligent manufacturing industry.”